Search results

Search for "physical vapor deposition" in Full Text gives 49 result(s) in Beilstein Journal of Nanotechnology.

SERS performance of GaN/Ag substrates fabricated by Ag coating of GaN platforms

Beilstein J. Nanotechnol. 2023, 14, 552–564, doi:10.3762/bjnano.14.46

- physical vapor deposition (PVD) methods have been tested to replace MS in coating GaN platforms with plasmonic metals. Pulsed laser deposition (PLD) is an interesting and still not fully explored alternative for the fabrication of SERS substrates [37][38]. Hence, our studies reported herein aimed to

- markedly different morphology, especially to the sharp edges and spikes. Materials and Methods Fabrication of GaN/Ag substrates Two physical vapor deposition methods, MS and PLD, were used to coat GaN platforms with Ag layers. The research aimed to compare the enhancement of the Raman signal on GaN/Ag SERS

A novel approach to pulsed laser deposition of platinum catalyst on carbon particles for use in polymer electrolyte membrane fuel cells

Beilstein J. Nanotechnol. 2023, 14, 190–204, doi:10.3762/bjnano.14.19

- [27]. Direct deposition of PtNPs can be attained by the use of various physical vapor deposition techniques such as magnetron sputtering [28], sputtering [29], e-beam evaporation [30], dual ion-beam assisted deposition [31], and pulsed laser deposition (PLD) [27][32][33]. Previously, PLD has been used

Combining physical vapor deposition structuration with dealloying for the creation of a highly efficient SERS platform

Beilstein J. Nanotechnol. 2023, 14, 83–94, doi:10.3762/bjnano.14.10

- approach reported here allows for an easy synthesis of a rather high sensible platform. Alternatively, more simple approaches for the synthesis of SERS-based sensors, such as direct physical vapor deposition (PVD) coating of natural micro- or nanostructured materials have been reported. For example, the

Design of a biomimetic, small-scale artificial leaf surface for the study of environmental interactions

Beilstein J. Nanotechnol. 2022, 13, 944–957, doi:10.3762/bjnano.13.83

- of structures that often do not correspond to the original wax type [20][42]. Due to the ring-shaped accumulation and the resulting pattern, this effect is called the “coffee drop effect” [47][48]. This undesirable effect can be avoided by the solvent-free process of physical vapor deposition (PVD

Sputtering onto liquids: a critical review

Beilstein J. Nanotechnol. 2022, 13, 10–53, doi:10.3762/bjnano.13.2

- , Czech Republic 10.3762/bjnano.13.2 Abstract Sputter deposition of atoms onto liquid substrates aims at producing colloidal dispersions of small monodisperse ultrapure nanoparticles (NPs). Since sputtering onto liquids combines the advantages of the physical vapor deposition technique and classical

- (Figure 1). In 1974, Yatsuya et al. used a liquid as a substrate during a physical vapor deposition (PVD) experiment. They thermally evaporated metals in vacuum onto silicon oil for NP production [9]. After the pioneering experiments of Yatsuya et al., depositions onto liquids were not mentioned in

Paper-based triboelectric nanogenerators and their applications: a review

Beilstein J. Nanotechnol. 2021, 12, 151–171, doi:10.3762/bjnano.12.12

- by stencil-assisted vapor deposition [103]. The arrays of small holes with various shapes and distributions are drilled on the stencil via laser cutting, and a layer of copper with thickness of 100 nm is deposited onto the electrode via physical vapor deposition. By combining the stencil-assisted

Fusion of purple membranes triggered by immobilization on carbon nanomembranes

Beilstein J. Nanotechnol. 2021, 12, 93–101, doi:10.3762/bjnano.12.8

- reflection absorption spectroscopy (IRRAS). Experimental Preparation of SAMs and CNMs NBPT was purchased from Taros Chemicals (Dortmund, Germany). Thermally evaporated Au films (300 nm) on mica supports (Georg Albert physical vapor deposition coatings) were used as substrates for the SAM preparation

Out-of-plane surface patterning by subsurface processing of polymer substrates with focused ion beams

Beilstein J. Nanotechnol. 2020, 11, 1693–1703, doi:10.3762/bjnano.11.151

- damage in polymer materials. The Pt60Pd40 alloy films were deposited by DC sputtering as described in [4], in a Cressington 208HR sputter apparatus. The Au films were deposited with an e-beam in a Cryofox Explorer 600 physical vapor deposition system. We have been using very thin metal films (5 and 15 nm

Optically and electrically driven nanoantennas

Beilstein J. Nanotechnol. 2020, 11, 1542–1545, doi:10.3762/bjnano.11.136

- deposition [41], or on dense silver island films created by pulsed laser deposition [42] or physical vapor deposition [43]. In [44], individual plasmonic nanotags are prepared by coating gold nanoparticle clusters with Raman reporters. This work explores the minimum number of tags required for obtaining a

Templating effect of single-layer graphene supported by an insulating substrate on the molecular orientation of lead phthalocyanine

Beilstein J. Nanotechnol. 2020, 11, 814–820, doi:10.3762/bjnano.11.66

- layer. Experimental A 10 nm thin PbPc film on single-layer graphene supported on a SiO2/Si substrate (SLG/SiO2/Si) was deposited using physical vapor deposition. The PbPc film was deposited at a base pressure of 1 × 10−5 mbar while the substrate was held at 100 °C. The deposition rate was 1–1.5 Å·s−1

Oblique angle deposition of nickel thin films by high-power impulse magnetron sputtering

Beilstein J. Nanotechnol. 2019, 10, 1914–1921, doi:10.3762/bjnano.10.186

- ][21] and substrate temperature [19], as well as while stacking into superlattices [23][24]. High-power impulse magnetron sputtering (HiPIMS), sometimes referred to as high-power pulsed magnetron sputtering (HPPMS), is a physical vapor deposition (PVD) technique based on pulsed power technology where

Fabrication and characterization of Si1−xGex nanocrystals in as-grown and annealed structures: a comparative study

Beilstein J. Nanotechnol. 2019, 10, 1873–1882, doi:10.3762/bjnano.10.182

- annealing. A rather recent variation of the magnetron sputtering technique, the so-called high-power impulse magnetron sputtering (HiPIMS), provides an alternative approach. It is an ionized physical vapor deposition method and has shown great promise in thin-film processing [25][26]. During HiPIMS the

Fabrication of phase masks from amorphous carbon thin films for electron-beam shaping

Beilstein J. Nanotechnol. 2019, 10, 1290–1302, doi:10.3762/bjnano.10.128

- ) were fabricated with a DWL66 laser lithography system (Heidelberg Instruments). After illumination of the unmasked regions, the resist was developed in AZ 726 MIF (Microchemicals GmbH). To deposit Cr, Pt and aC, electron-beam physical vapor deposition (PVD, PVD75 by Kurt J. Lesker Company) was used

Revisiting semicontinuous silver films as surface-enhanced Raman spectroscopy substrates

Beilstein J. Nanotechnol. 2019, 10, 1048–1055, doi:10.3762/bjnano.10.105

- nanostructures fabricated using physical methods, such as semicontinuous metal films obtained via electron beam physical vapor deposition. In these studies, we investigate the influence of morphology of semicontinuous silver films on their SERS properties. The morphologies studied ranged from isolated particles

- nanostructures can be a source of additional SERS signals [15], which may complicate SERS analysis with their use. Various physical methods may be used to fabricate SERS substrates. Usually in these techniques silver or gold is deposited by physical vapor deposition (PVD) techniques. Nanostructures are obtained

Biocompatible organic–inorganic hybrid materials based on nucleobases and titanium developed by molecular layer deposition

Beilstein J. Nanotechnol. 2019, 10, 399–411, doi:10.3762/bjnano.10.39

- enables control of cell–surface interactions, which plays a major role in controlling the bioactivity of solid surfaces. Biocompatibility can be enhanced by coating the surface using various thin film deposition techniques such as chemical vapor deposition (CVD), physical vapor deposition (PVD) or atomic

Femtosecond laser-assisted fabrication of chalcopyrite micro-concentrator photovoltaics

Beilstein J. Nanotechnol. 2018, 9, 3025–3038, doi:10.3762/bjnano.9.281

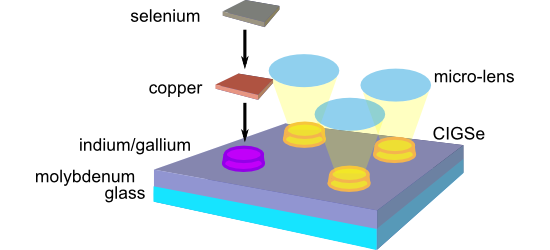

- and opportunities of the novel approaches to realize this cell concept. The first approach for microabsorber fabrication summarized here is based on the growth of metallic precursors (indium islands) on laser-structured substrates (molybdenum on glass) by means of physical vapor deposition (nucleation

- -structured substrates. Indium has a strong tendency towards island growth during physical vapor deposition (PVD) on molybdenum substrates. On smooth molybdenum surfaces, indium islands nucleate with random spatial distribution. Indium prefers to accumulate on rough areas. Hence, preferential island

Pattern generation for direct-write three-dimensional nanoscale structures via focused electron beam induced deposition

Beilstein J. Nanotechnol. 2018, 9, 2581–2598, doi:10.3762/bjnano.9.240

- uses a layer-by-layer based technique [4]. The design of the desired 3D structure is partitioned into horizontal slices parallel to the substrate surface. For each slice a full set of structure-definition steps, typically combining physical vapor deposition and UV or electron beam lithography, are

Electromigrated electrical optical antennas for transducing electrons and photons at the nanoscale

Beilstein J. Nanotechnol. 2018, 9, 1964–1976, doi:10.3762/bjnano.9.187

- connected optical antenna is a Au constriction formed between two fan-out electrodes laying on a glass cover slip. We use electron-beam lithography and standard physical vapor deposition to produce gold constrictions and the proximity electrodes. The thickness of the Au layer is typically 50 nm, and we use

- processing. We realize the implementation of tunneling antennas on a TiO2 waveguide through a multi-step process. First, a 85 to 110 nm thick titanium dioxide layer is deposited by physical vapor deposition on a clean glass substrate. Then, the Au backbone that will subsequently define the electrically

Nanoporous silicon nitride-based membranes of controlled pore size, shape and areal density: Fabrication as well as electrophoretic and molecular filtering characterization

Beilstein J. Nanotechnol. 2018, 9, 1390–1398, doi:10.3762/bjnano.9.131

- membrane. Experimental details are summarized in Table S1 in Supporting Information File 1. First, in Figure 1a an approximately 55 nm thick sacrificial layer of silicon oxide is deposited on top of the SiN membrane by electron beam physical vapor deposition (EBPVD). After that, Au NPs (typical diameter ca

Effect of annealing treatments on CeO2 grown on TiN and Si substrates by atomic layer deposition

Beilstein J. Nanotechnol. 2018, 9, 890–899, doi:10.3762/bjnano.9.83

- sputtering [7], e-beam [16], physical vapor deposition [17], chemical vapor deposition (CVD) [18], and atomic layer deposition (ALD). The latter has been explored by using different precursors, e.g., Ce(thd)4, Ce(iPrCp)3 and Ce(mmp)4) [19][20][21][22][23], obtaining as-deposited film with polycrystalline

Au nanostructure fabrication by pulsed laser deposition in open air: Influence of the deposition geometry

Beilstein J. Nanotechnol. 2017, 8, 2438–2445, doi:10.3762/bjnano.8.242

- their fabrication. Such applications require contamination-free nanostructures, suggesting that the development and use of physical nanofabrication methods is further warranted. One of the physical vapor deposition techniques widely applied in bottom-up nanotechnology is pulsed laser deposition (PLD

Bi-layer sandwich film for antibacterial catheters

Beilstein J. Nanotechnol. 2017, 8, 1982–2001, doi:10.3762/bjnano.8.199

- vacuum apparatus. Chemical vapor deposition differs from physical vapor deposition by the fact that one or more substances are evaporated and undergo a chemical reaction during transport to a surface. The main advantage of CVD is conformal coating even on heavily rugged surfaces, which makes it the

- , the adhesion of the grains is improved. But the main purpose of the cap layer is the exact control of the release rate of Ag+ ions. This is achieved by tuning the porosity of the cap layer as a function of the layer thickness. Chemical vapor deposition differs from physical vapor deposition by the

Laser processing of thin-film multilayer structures: comparison between a 3D thermal model and experimental results

Beilstein J. Nanotechnol. 2017, 8, 1749–1759, doi:10.3762/bjnano.8.176

- <100> coated by an aluminum layer with the thickness of 1 μm. c-silicon wafer <100> coated by a very thin gold layer with a thickness around 100 nm. The thin films were deposited on the surface of the samples using physical vapor deposition technique and the samples were purchased with thin-film

Optical response of heterogeneous polymer layers containing silver nanostructures

Beilstein J. Nanotechnol. 2017, 8, 1065–1072, doi:10.3762/bjnano.8.108

- physical vapor deposition methods require high energy sources, such as lasers [16], whereas chemical synthesis produces, among other shapes, nanospheres and nanoprisms of different sizes in water at room temperature. Taking advantage of the size and shape versatility of this chemical synthesis, we aim to

The integration of graphene into microelectronic devices

Beilstein J. Nanotechnol. 2017, 8, 1056–1064, doi:10.3762/bjnano.8.107

- methods have been proposed [7], which can be grouped into the following categories. 1.1 Ex situ transfer The CVD growth substrate can either be a copper foil, which is most commonly used, or a Cu film deposited by physical vapor deposition (PVD) on a silicon wafer substrate with a diffusion barrier